Ruisheng Glass Liquor & Spirits Bottle Manufacturer

Ruisheng is a leading glass bottle manufacturer in China.

We have more than 16 years of experience in glass bottle manufacturing.

We currently have over 9000 different glass bottle styles available.

Ruisheng exports our glass bottles to more than 30 countries.

Our glass bottles are trendy in Europe, America, the Middle East, Asia, and Africa.

We look forward to being your partner.

Our Glass Bottle Production Capacity

3

Production Plants

11

Production Lines

5

Furnaces

1,000,000+

Pcs/Day

16

Years’ experience

1000+

Employees

Our Glass Bottles Types

You can use our glass bottles for alcoholic spirits, such as vodka, whiskey, brandy, and tequila.

Additionally, we manufacture glass bottles for water, beverages, and olive oil.

Our Liquor Bottle Sizes

First, we have 10ml and 100ml glass bottles for small capacities.

They are perfect for decorative bottles, giveaways, or personal use.

These small bottles are beautiful in shape.

They’re easy to carry, making them ideal as gifts or collectibles.

If you need a medium-capacity bottle, we have 250ml and 500ml options.

These bottles can hold significant amounts of alcoholic beverages.

They are perfect for bars, restaurants, or family gatherings.

Their simple design makes them easy to pair with a variety of drinks.

Besides, we have 750ml and 3L glass bottles for significant capacity needs.

These bottles are perfect for wholesale, winery, or important events.

They are big enough to hold more alcohol, so customers can enjoy their meal as much as they like.

Contact us to learn how we can help you with your glass bottle needs.

Our range of bottles includes sizes between 10ml and 3L.

10ml, 100ml, 150ml, 200ml, 250ml glass bottles

375ml, 500ml, 700ml, 750ml, 1000ml glass bottles

1200ml, 1500ml, 2000ml, 2500ml, … 3000ml glass bottles

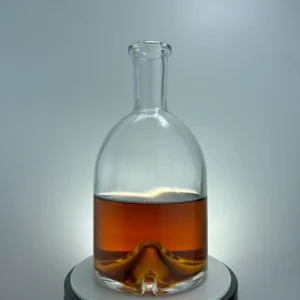

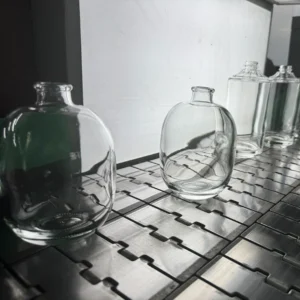

Our Glass Bottle Shapes

Our glass bottles come in a variety of standard shapes.

Each has unique designs and features to suit different brands and styles.

First, we have the traditional cylindrical glass bottle.

This shape is simple and classic, suitable for all types of alcoholic beverages.

Secondly, we also offer square and rectangular glass bottles.

Square and rectangular bottles are generally more stable. They are also easier to stack and pack.

We also offer non-traditional shapes—for example, round-bottomed, oval, and flat bottles.

Our Glass Bottle Color

Our glass wine bottles are available in a variety of standard colors.

First, we have clear glass bottles. The clear bottle showcases the color and clarity of the wine.

This classic and simple color is suitable for all types of liquor.

Secondly, we offer amber glass bottles. The amber bottle gives you an ancient and elegant feel.

In addition, we have green, red, black, and blue glass wine bottles.

Green bottles are often associated with wine and champagne.They give them a fresh and natural feel.

Blue bottles are often used to bottle cocktails and liqueurs. They add a touch of mystery and summer.

These colors catch the consumer’s eye and highlight your brand image.

Our glass wine bottles are available in a variety of standard colors. Each color gives your product a unique style and appeal.

Custom Bottle Caps & Stoppers

Our glass bottles come with a variety of standard stoppers.

They meet the needs of different customers.

The first is traditional plastic stoppers. They are reliable and durable.

They can maintain the freshness and quality of the liquid.

Next are corks, which give an elegant look and are suitable for high-end wines and spirits.

We also provide metal bottle stoppers. They can keep the liquid in the bottle fresh.

glass bottle cap

wooden bottle cap

Colorful bottle caps

cork bottle cap

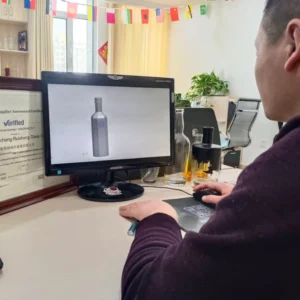

Our glass bottle manufacturing process

Design:

First, the design team works on the glass bottle’s look and size based on what customers want and what’s popular. They consider things like what the bottle will be used for, how big it should be, and the style.

Preparing the Materials:

Quartz sand, soda ash, and limestone are the main ingredients needed to make glass bottles. These ingredients are weighed carefully and mixed.

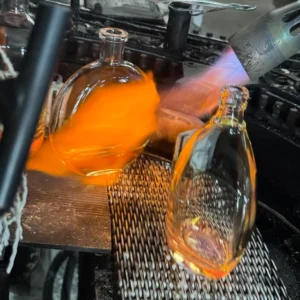

Melting:

The mix is put into a big furnace and heated until it melts into liquid glass.

Shaping:

The liquid glass is put into a mold and gets shaped into a glass bottle by blowing, pressing, or stretching it.

Cooling:

After shaping, the glass bottle is put in a cooling oven and cooled slowly. This ensures that the temperature is even inside and out, preventing stress inside the glass.

Checking and Fixing:

Once cooled, workers check the bottles. If there are any mistakes or problems, they fix them or make a new one.

Packing:

Lastly, the bottles that pass the check are packed and ready to be sent to the customer. How they’re packed can be changed based on the customer’s needs, such as putting them in boxes or adding labels.

liquor bottle manufacturing service

Unique Designs

We can provide glass bottle designs in various styles and shapes.

In addition, we can also provide silk screen printing, hot stamping, spray painting, or stickers.

Wholesale Price

We are a professional glass bottle manufacturer. We can provide you with high-quality glass bottles at the lowest cost.

Plenty of Options

We can produce vodka, whiskey, rum, gin, tequila, and brandy bottles.

Rich Export Experience

With rich export experience, we know better what customers are most concerned about and care about. You will obtain a satisfactory glass bottle from us. Welcome your inquiry!

Our packaging & shipping

We use high-strength packaging materials to protect the glass bottles.

These materials reduce the risk of collision and damage to bottles during transportation.

We usually use wooden boxes or cartons for international transportation for outer packaging.

In addition to packaging, we work with professional logistics partners.

We will provide you with detailed shipping information.

Blogs

Get in touch

We appreciate your visit to our website! If you have any inquiries, suggestions, or opportunities for collaboration, please don’t hesitate to contact us. We are here to listen, assist, and explore potential partnerships.